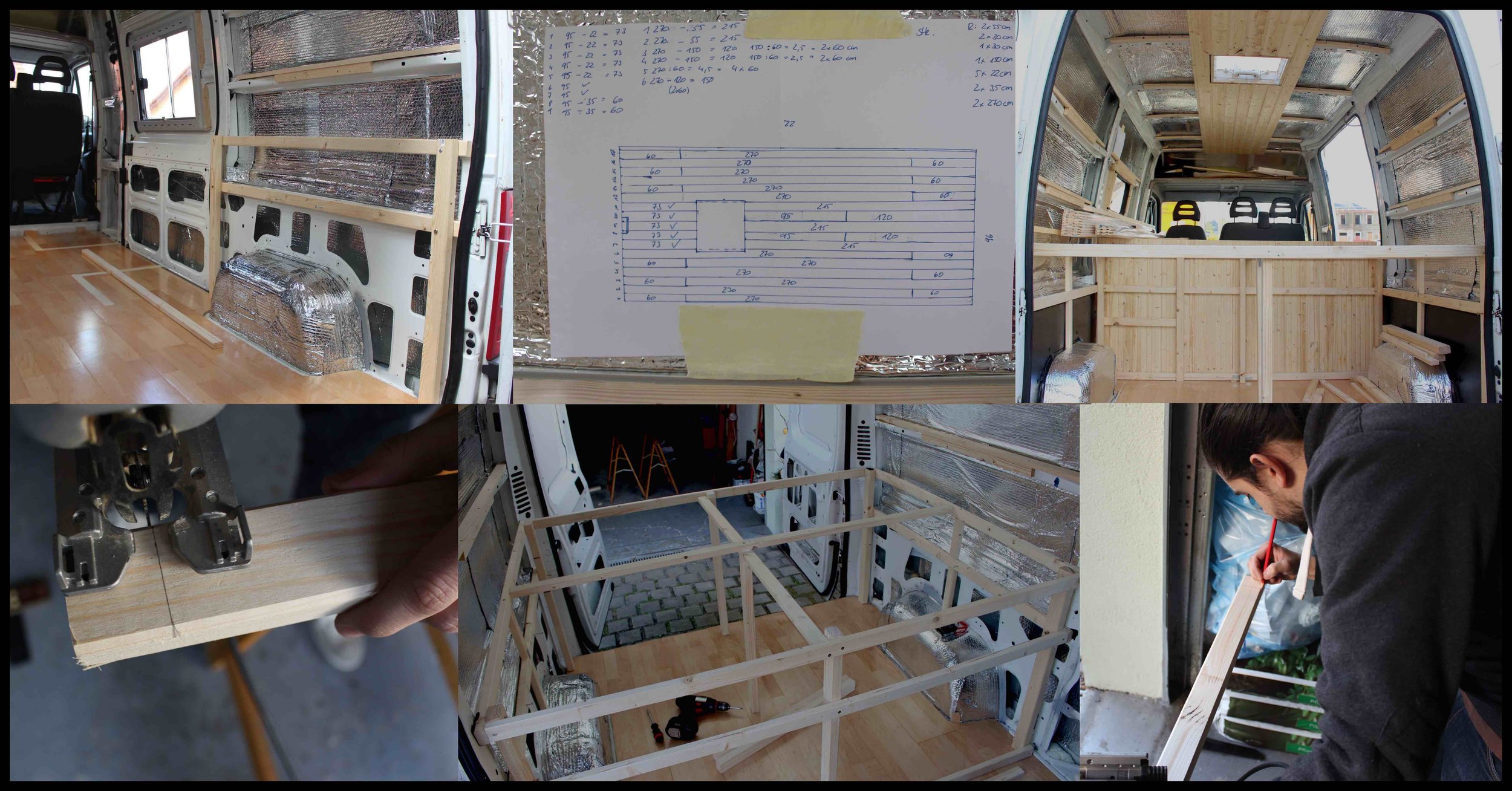

The conversion part 4

Cupboards

Our main concern when it came to cupboards was weight. We wanted them to be as light as possible as we knew they’ll only be held by a few screws and apart from holding the weight of the cupboards themselves, the screws would also of course need to support the weight of what’s inside. So first of all we came up with a shape that considers the slanting of the walls at the rear end of the van. Importantly though, the shape and size needed to give us enough space to store everything, while at the same time not being too big so we don’t bang our heads every time we get out of bed! Not easy to find the perfect balance that’s for sure.

Basically we built them as light but sturdy frames, with thin panels closing them off and making them look like proper cupboards. The bottom and top parts are 3mm mdf which is very light but covering a small space, still strong enough to carry our things. The sides are made of 6mm plywood which we glued and nailed and the door is also 6mm plywood.

Chairs and Table

We wanted the design of the chairs to be as easy as possible and also to provide storage. Basically just boxes, one built between the frame of the kitchen and the bed and the other chair opposite was built in front of the side door. This is nice as in summer you can have the door open and just sit there enjoying the view. The chair next to the kitchen provides us with storage for the grey water tank and now also for our newly connected gas heater. The other one provides storage for food. We left the back of the side door chair open so that it’s easy to fill with stuff when coming back from the shops and the seat also folds up so you can access all the food from inside the van. The picture below make this a bit clearer.

The table was a little bit tricky to design at first. We weren’t 100% sure what would be the best kind of set-up for our needs. We also realised at one point that once the table is up there is a tiny amount of space between the kitchen and the end of the table so it would be very difficult for the person sitting next to the kitchen to get in and out. This is what inspired us to design something that slides to the left and right. We also didn’t want something that is always in the way because that would just be very frustrating in such a small living space. For his reason the table is not only slidable but also foldable and perfect for our needs. Finally we put two layers of varnish on everything which gives it all a nice classy look, protects it all from moisture and makes it easier to clean/wipe down.

The kitchen

This is our little power hub. The simple but sturdy frame, (which we already introduced in an earlier post), manages to hold our 70L freshwater tank, our compressor cool box (fridge), the water pump system, gas manifold and to the side of it, a toilet room/shower area. The tank and fridge we bought new and the fridge especially was an important investment as we wanted a powerful but efficient (low energy) model that would last us a long time. Finding this perfect combination in one model was not easy and we ended up buying three fridges before finding the model we have now from the company Waeco. At first our priority was to find a three way model which is a cool box that runs on 230V,12V and gas. We wanted to be able to switch to gas mode in case we, so to speak, run out of sun and therefore electricity. A 3 way cool box is mostly a toolbox that works through absorption technology which is also completely silent and we thought that this would be very important in such a small place. So with all of these requirements in mind, we ended up buying a used model in an adrenaline filled auction on eBay. Unfortunately though, this turned out to not work on 12V anymore and the overall condition was pretty poor.

So after this bad experience, we decided to buy a new model. We made, what we thought was a well informed decision, to buy a powerful model from a well established camping equipment company called Dometic. It was in perfect new condition, looked good and fit perfectly in the allocated space under the kitchen worktop. Unfortunately though, we didn’t pay enough attention to the energy consumption and after having it run for 4 days it drained our battery completely. We read lots of good reviews from people with camper vans but what we only realised afterwards was that these people were most likely running the fridge on external, camp-site power and not solar power.

So after all this frustrating rigmarole we are now the owners of a beautiful compressor cool box that uses next to no energy at all, while still managing extremely good cooling performance. Our worries of the compressor being too loud were all nonsense, as once the fridge reaches the desired temperature, it very rarely even comes on and it’s not loud at all. Using it on gas in an emergency is unfortunately not an option this fridge offers but because it is so efficient we have never run out of battery with it. The other good thing about it is it can even be put on to a freeze mode!

Yes, these are the things you get excited about when building a camper van.